Battery Testing Services

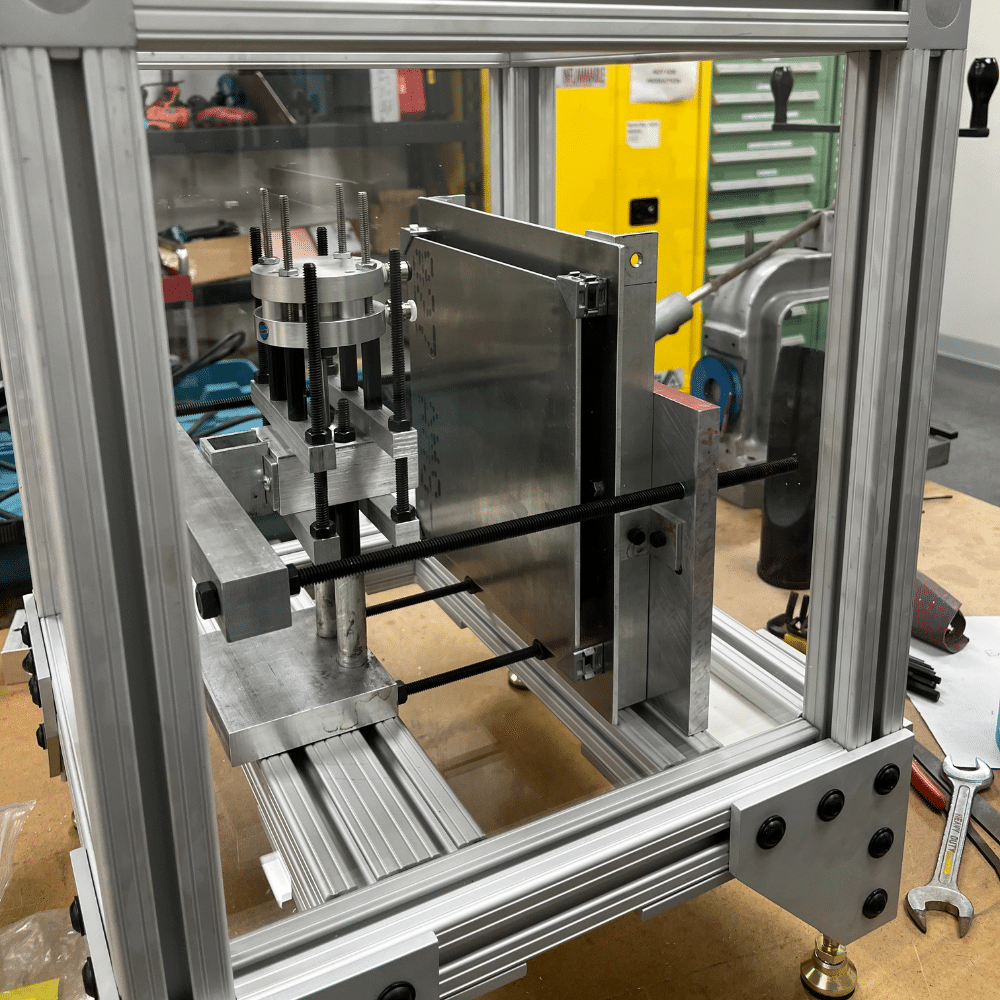

Cell Screening

KULR’s Cell Screening Line is a crucial tool for battery manufacturers and integrators who want to enhance the safety, performance, and lifespan of their battery packs. The Cell Screening Line utilizes advanced technology to measure voltage, temperature, and impedance of individual battery cells, analyze the data to identify potential issues and optimize the battery pack’s performance. In manned spaceflight, adhering to the JSC EP-WI-37A specification is crucial for ensuring safety and reliability. By rigorously testing and screening battery cells to this standard, NASA and its partners can confidently expect their battery systems to perform safely and reliably in the challenging conditions of space and other markets that require high reliable battery solutions.

OUR CELL SCREENING TESTING PROVIDES:

- Charge retention

- Mass and dimensional consistency

- Visual defect, corrosion

- Meets NASA’s spaceflight requirements

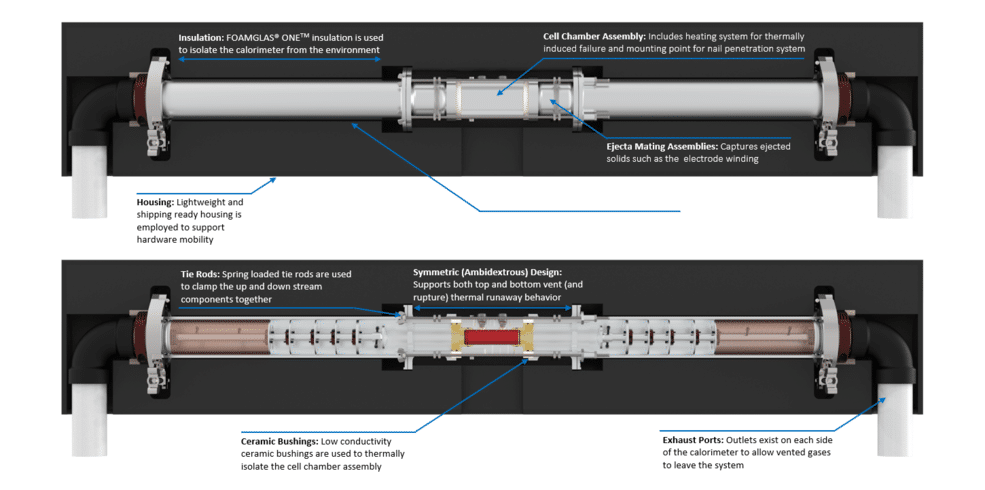

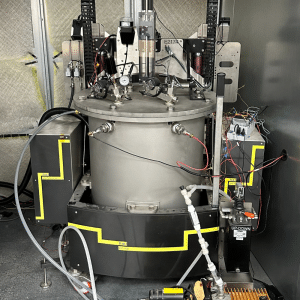

Fractional Thermal Runaway Calorimetry Testing

KULR’s Fractional Thermal Runaway Calorimeter (FTRC) testing service provides critical information about the safety and performance of lithium-ion batteries. FTRC testing is designed to simulate extreme conditions that can cause lithium-ion batteries to overheat and potentially catch fire, such as impact, puncture, or overcharging. By subjecting batteries to these extreme conditions, FTRC testing can help identify potential safety issues and inform the design and manufacturing of safer, more reliable batteries. This can ultimately lead to safer products, reduced risk of accidents, and increased consumer confidence in the safety of lithium-ion batteries.

OUR FRACTIONAL THERMAL RUNAWAY CALORIMETRY TESTING PROVIDES:

- Provide critical information about battery safety and performance

- Measures heat released during thermal runaway reactions

- Total Energy Yield vs Fractional Energy Yield

- Heat Rate and Heat Flux Analysis

- Minimizes risk of recalls or liability claims

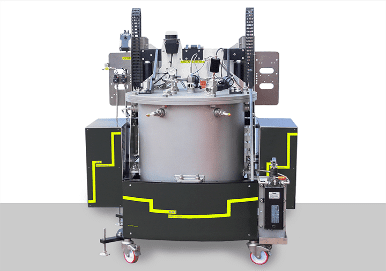

Bomb Calorimetry

KULR’s Bomb Calorimetry Testing is a method used to measure the energy content of a substance by burning it under controlled conditions. This testing is particularly useful in the field of energy storage, as it allows for the accurate determination of the amount of energy that can be released by a given material. By providing precise energy measurements, Bomb Calorimetry Testing can help companies develop more efficient and effective energy storage solutions, which can have a significant impact on the performance and sustainability of a wide range of applications, from electric vehicles to renewable energy systems.

OUR BOMB CALORIMETRY TESTING PROVIDES:

- Heat-Wait-Seek:

Accelerating Rate Calorimetry (ARC) Test Profile @ 2°C / min ramp rates - Determine separator breakdown, anode/SEI decomposition, acceleration temperature, and trigger temperature thresholds

- Collect gas samples with HOKE system for post-test analysis

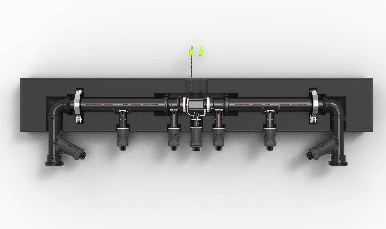

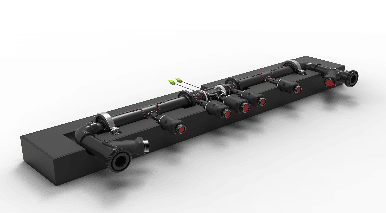

Impingement Zone Mapping (IZM)

KULR offers Impingement Zone Mapping Testing services, which is a thermal imaging technique used to measure temperature variations and identify hot spots in electronic devices. By identifying areas of high temperature, Impingement Zone Mapping Testing can help companies optimize the cooling systems of their electronic devices, leading to improved performance and increased reliability. This testing technique is particularly useful in the design and development of electronic products, where thermal management is crucial for the safe and effective operation of the devices.

OUR IMPINGEMENT ZONE MAPPING TESTING PROVIDES:

- Characterization of ejecta behavior (incl. velocity) in an open format

- Determine evolution of impingement zone shape, size, and intensity (heat flux)

- 360 view mapping with high-speed cameras.

- Improved battery performance through better understanding of cell behavior

- Reduced risk of failure by identifying issues before they occur

- Greater design flexibility with a wider range of cell options